Hydrocyclones at Stoilensky Mining and Processing Plant

Stoilensky Mining and Processing Plant, a part of NLMK Group, processes iron ore and is a leading innovator. In 2020, Sever Minerals took part in the implementation of a comprehensive project for the construction of a repreparation building for Stoilensky Mining and Processing Plant. In the process of project implementation, it was necessary to achieve two goals: increase the production volume from 37 to 42 million tons of ore per year, and the iron content in the concentrate up to 68%.

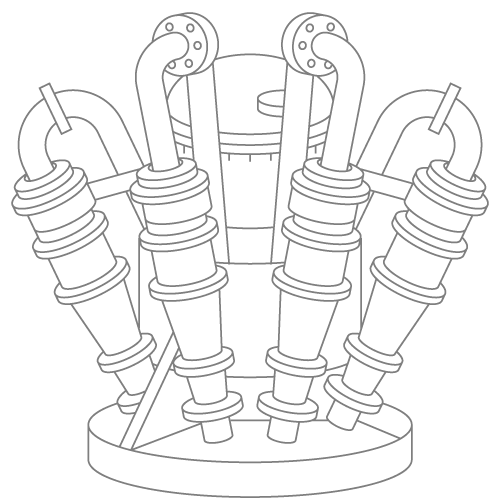

As a design solution, Sever Minerals proposed automated hydrocyclone units. Each consists of 20 units of conical hydrocyclones with a diameter of 350 mm. The plants work in a closed cycle with VTM-4500 vertical mill.

Multotec hydrocyclones feature low-pressure classification, which both improves classification performance compared to hydrocyclones operating at 2–2.5 bar, and also increases the service life of hydrocyclone wear parts and pumping equipment.

Hydrocyclones is controlled by a set of automation units, which makes it possible to automatically maintain important parameters of the classification unit operation: pressure at the inlet to the hydrocyclone, stability of the set level in the sump of the feed pumps and density of hydrocyclones feeding.

Sever Minerals service supervised the installation of hydrocyclones and participated in the installation of VTM-4500 vertical mills. The installation of the mills was successfully completed in December 2019, and the hydrocyclone pump plant was completed in May 2020. Now the stationary service continues to maintain this equipment.

Increase in plant productivity, increase the iron content in the concentrate with automated hydrocyclones

The result of the project is an increase in the productivity of ore processing sections from 1,120 to 1,330 tons per hour, from 37 to 42 million tons per year. Simultaneously with the increase in productivity, the iron content in the concentrate increased from 66.5% to 68.00%.

Every metallurgical enterprise strives to produce competitive raw materials for the market, increasing the iron content in the concentrate, which makes it possible to obtain a product of higher quality. The project experience allows us to quickly and efficiently solve similar complex tasks in the iron ore industry.

Installed equipment

- Metso MR-500 pumps

- Three clusters of 20 hydrocyclones

- VASA 70−10–200 series pumps

- Shut-off and control valves

Achieved capacity

1,330 tons per hour