Upgrade of Kovdorsky GOK

Enhancing capacity through the upgrade of crushing equipment

Kovdorskiy Mining and Processing Plant, part of EuroChem Holding, is one of the leading enterprises in the Northwest of Russia. The enterprise core business is complex processing of mineral raw materials and production of three concentrates: iron ore, apatite, and baddeleyite one.

Kovdorskiy GOK is systematically upgrading its entire equipment fleet in order to increase productivity and efficiency.

As part of the upgrade, it was necessary to replace outdated crushers of coarse and medium-small crushing stages to increase productivity, improve product quality and reduce scheduled and emergency downtime periods.

Upgrade of Kovdorskiy Mining and Processing Plant

Sever Minerals have thoroughly studied the challenges the new equipment would cope with and operating conditions. Ore samples were sent to Metso’s lab in Finland to determine the physical and mechanical properties of the feed. After all, the optimal solution giving the client a possibility to achieve the required performance and crushing product size, was presented as several projects:

- three Metso C200 jaw crushers and grate screens at the coarse crushing site;

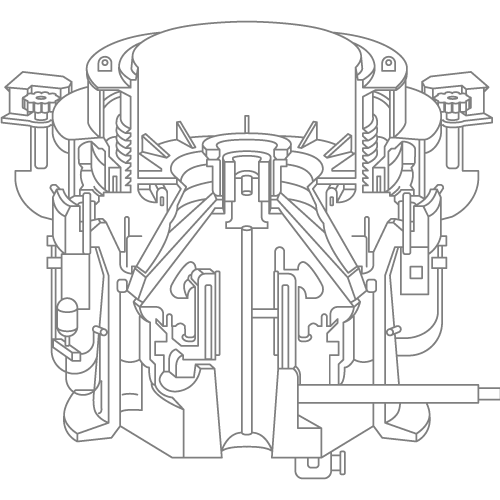

- two Metso HP500 cone crushers at medium-fine crushing site;

- laminated feeder and a roller screen feeder at medium-fine crushing site.

Implementation of the projects has already increased efficiency and reduced expenses of crushing apatite-magnetite ores at Kovdorskiy Mining and Processing Plant. It is planned that the project implementation will be ended in 2020.

The upgrade will result in the crushing plant’s capacity exceeding 21 million tons per year, while improving the quality of the resulting crushed material and reducing operating expenses.