Modernisation of Karelsky Okatysh JSC

Mining and processing plant Karelsky Okatysh JSC is one of the leaders in the iron ore industry in Russia.

The management of Karelsky Okatysh JSC decided to install equipment in one section from each supplier participating in the tender in order to test the proposed technologies. The installation and testing of the sections was carried out from January to April 2015.

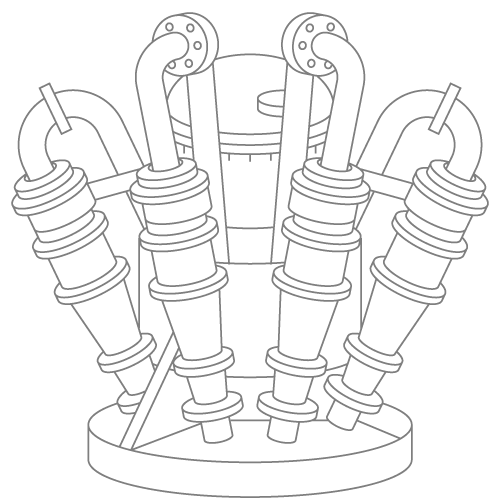

As a result of all the tests carried out in 2015, 44 pump-hydrocyclone units were installed in the technical sections of the plant for the first and second admission, as well as for the preliminary and control classification. The units were equipped with Metso pumps and pipelines, Multotec hydrocyclone batteries, Weg engines and Danfoss Aqua Drive frequency inverters. Sever Minerals service specialists carried out the installation and commissioning of the equipment from December 2015 to March 2016.

Modernisation of Karelsky Okatysh JSC

Project

Increased factory productivity through modernization of pumping and hydrocyclone units.

- 46Hydrocyclones

- 66Cyclones HC600

- 84Cyclones VV350

- 46Metso MD series pumps

In 2017, the management of Karelsky Okatysh JSC set a new task: to improve the quality of the finished product. To solve this problem, specialists from Sever Minerals and Multotec proposed to modernize the VV350 hydrocyclones installed at the third and fourth stages.

The proposed technical solution included a partial redesign of the standard VV350 cyclone. The length of the cyclone body was increased using an additional cylindrical section, and the angle of the conical part was sharpened. The upgraded VV350 cyclones increased the efficiency of preliminary and control classification. The use of modernised hydrocyclones at the third and fourth stages of classification led to an increase in the qualitative indicators for the overflow products of classification stages and the concentrate refinement unit in general.

Efforts are continuing to increase the iron content in the concentrate. In April 2019, two new pumps with hydrocyclones of a smaller size (250 mm) were delivered to the enterprise. The body of the new cyclones is made of steel with a removable rubber lining. Cyclones of smaller diameter should increase the quality of the finished product by ensure finer separation from sludge. Sever Minerals specialists are now working together with technicians from Karelsky Okatysh JSC to test equipment and set up a smooth process.

The modernisation of Karelsky Okatysh JSC produced impressive results in 2017:

- Increased capacity in the ore and concentrate section.

- Reduced specific consumption of grinding balls for ball mills.

- Reduced specific energy consumption per tonne of concentrate produced.

- Increased service life for pump flow parts.

- Reduced costs for maintenance and repair of pumping units.