Upgrade of Yubileyny Mining and Processing Plant

Amur Zoloto is one of the 20 largest Russian gold mining companies in terms of gold production. In 2018, the company produced 1,515 kg of gold. The company is a promising producer in one of the most developed (in terms of gold mining) regions of Russia, Khabarovsk Krai.

Within the framework of cooperation with Amur Zoloto, Sever Minerals made its first delivery of Metso crusher and screener in 2016 for the Perevalnoye deposit and continued cooperation on the project of Yubileyny Mining and Processing Plant upgrade.

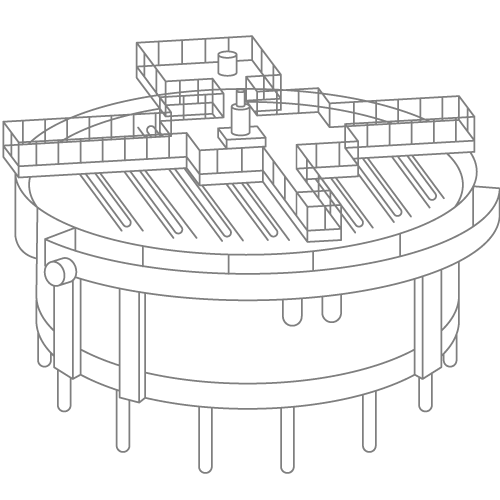

Yubileyny Mining and Processing Plant includes the underground mine at the Krasivoye deposit and the gold extraction plant.

The deposit has two ore bodies with a thickness of about 7 m and grades in the subsurface of 11.2 g/t and 8.4 g/t. The first ore body has a strike length of about 150 m and the second one has a strike length of about 38 m.

To extract gold, a gravity-flotation enrichment scheme was adopted, with the extraction of rich gravity concentrate, flotation enrichment of gravity tailings, as well as subsequent hydrometallurgical processing of gravity concentrates using intensive cyanidation technology.

Enhance the plant productivity through equipment upgrade

Project

Enhance the plant productivity through equipment upgrade.

Our company was tasked with increasing the productivity of the plant by 25% and simultaneously increasing the life of the equipment, as well as reducing power consumption and reagents fed into the process. Further it was necessary to solve the problem of reducing the footprint of the equipment to be installed.

This solution was implemented jointly with Irgiredmet Research Institute of Noble and Rare Metals and Diamonds.

Commissioning and supervised installation works were carried out by service engineers of Sever Minerals. All the declared performance characteristics were confirmed by test run; the equipment was put into operation.

As a result of installing new equipment, Yubileyny Mining and Processing Plant reached a processing capacity of up to 130,000 tons of finished ore per year.

In order to solve the problem, experts of Sever Minerals proposed to arrange the equipment as follows:

- Metso MB 352 hydraulic hammer for crushing oversize material before the first crushing stage

- Мultotec HC 350 hydrocyclones with scrolled evolute design, providing high classification quality and, at the same time, longer service life of wear parts (sand and drain nozzles and housing liners)

- Metso HM75, HM150 and MM100 pumps

- Metso LTK 150-F4 laminated settler with its small dimensions and high throughput rate and clean overflow due to large settling area. Here power and flocculants consumption is much lower as compared to conventional radial thickeners

- local automated control system to control the thickening process

- 130K ton/hour

- 16Capacity, ton/hour

- 25Enhance factory performance, %

Project indicators

- Feed material: rock-forming minerals

- Abrasiveness: high

- Humidity: 4%

- Initial capacity: 9 ton/hour

- Achieved capacity: 16 ton/hour

Installed equipment

- Metso MB 352 rock crusher

- Multoteс HC 350 hyrdocyclones

- Metso HM pumps

- Metso LTK 150-F4 laminated settler

- Weg and Danfoss solutions-based automation system